The Digital Future

The Digital Future: Reimagining Ceramic Education in the 21st Century

If a line drawn in clay can be said to mark time, imagine all the different ways that line can be created today. It can be scraped with a fingernail onto the surface of moist clay, leaving a trace of unevenness that signifies the distinct touch of a human. The line can also be incredibly exact, when cut by a laser beam or by a 60,000 pounds per square inch (psi) robotic water-jet cutting system.

Consider the state of ceramics today, as our culture settles into the information era. Those of us who work in clay have more options than ever seemed possible. We can cut, engrave, and reproduce ceramic artworks robotically, or we can enact age-old rites of fire by hand-stoking a kiln for days on end. In 2009, the Museum of Art and Design in New York City mounted a show called "Object Factory: The Art of Industrial Ceramics." The exhibition included many European designers whose work emphasizes "important technological advances in ceramic material." Little evidence of handwork was visible; designers sliced, deconstructed, and cleverly reassembled ceramic elements premade by recognized manufacturers. These hybridized and reconfigured ceramic objects signal that digital technologies are making their way onto the list of tools available to artists and designers who work in clay. Museum shows often highlight previously established patterns of artmaking. In 2006, I curated an exhibit titled "The New Utilitarian" at Lewis and Clark College, in Portland, which examined the place of new technology in the ceramic arts. This exhibit included a diverse group of artists, such as Bennett Bean, who established his reputation in the 1980s making handbuilt vessels and then switched over to using a three-dimensional imaging program to create strong and intensely beautiful ceramic knives. Also included were Garth Johnson, Gary Carlos, and other emerging artists who have started to use these digital technologies with intriguing results, as well as mid-career artists such as Steve Thurston.

As computer-assisted technologies emerge in our rapidly changing digital landscape, we educators stand at a critical place. Our field of ceramics has always been process-based and equipment-heavy. In many studio art departments, the ceramics area has begun to expand and merge with larger spheres of design and contemporary art. Given this already-full plate for art educators who work in ceramics, what are our obligations for adding new technologies into our curriculum? Will these tools become another option for creating meaningful art and well-designed objects? Will these technologies prove truly useful and be equitably available to all students? How and where will they fit into the current model of ceramic education? How do we weigh and balance the value of hand skills in this new mix? These issues are significant and need to be discussed when creating future curricula in higher education for all of the studio arts, not just the ceramics studio. Digital equipment and applications are significant tools for creating innovative artworks and demonstration examples in the classroom. The following are some new technologies that could be integrated into a curriculum standing at the axis of ceramics, sculpture, and digital media.

Digital Ceramic Printing

Rapid Prototyping

Rapid prototyping is the automatic construction of physical objects using additive manufacturing technology with ceramic materials as well as digital printing. In rapid prototyping, 3-D modeling software is used to design the form, then the design file is sent to a printer that outputs a three-dimensional object made of powder and resin. Several innovators, such as John Balisteri from Bowling Green University, have started to experiment with using ceramic materials in these printers and have fired them with varying results (see The Studio Potter, Vol. 37 No. 1). There are also 3-D scanners, which can capture the geometry of an existing form and create a computer model that can subsequently be altered and "printed." Michael Eden, from the United Kingdom, has been working with this process and achieving remarkable results. His artwork is an excellent example of how a 3-D printer can shape ceramics in a way that would be nearly unattainable otherwise.

Laser Cutting

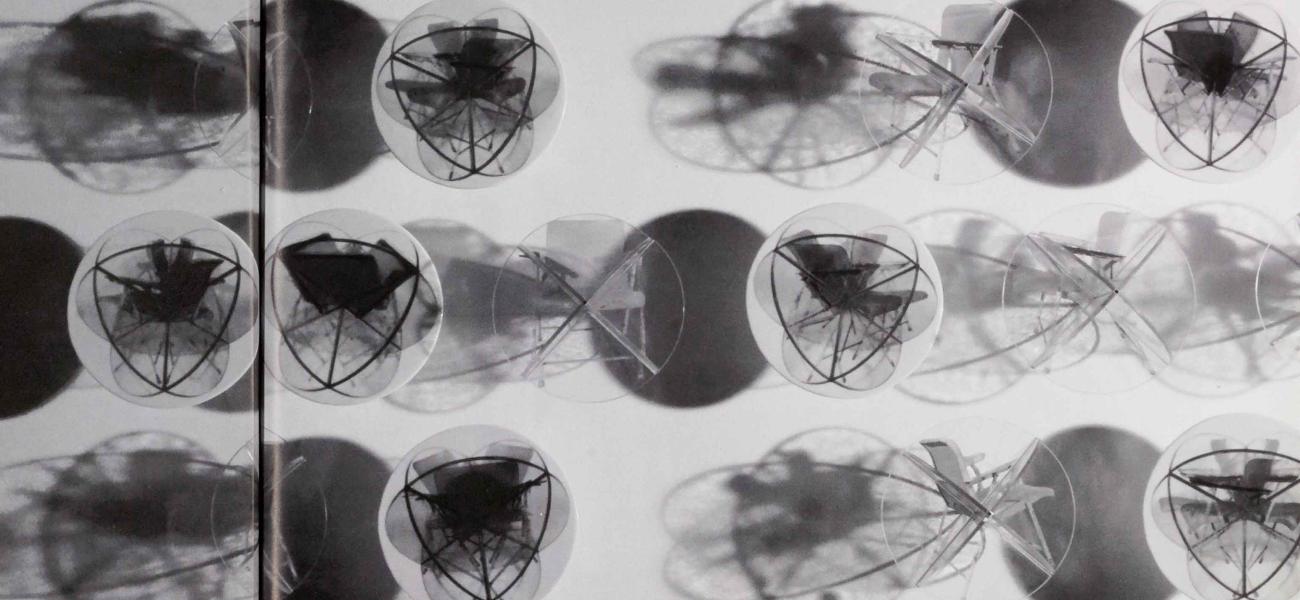

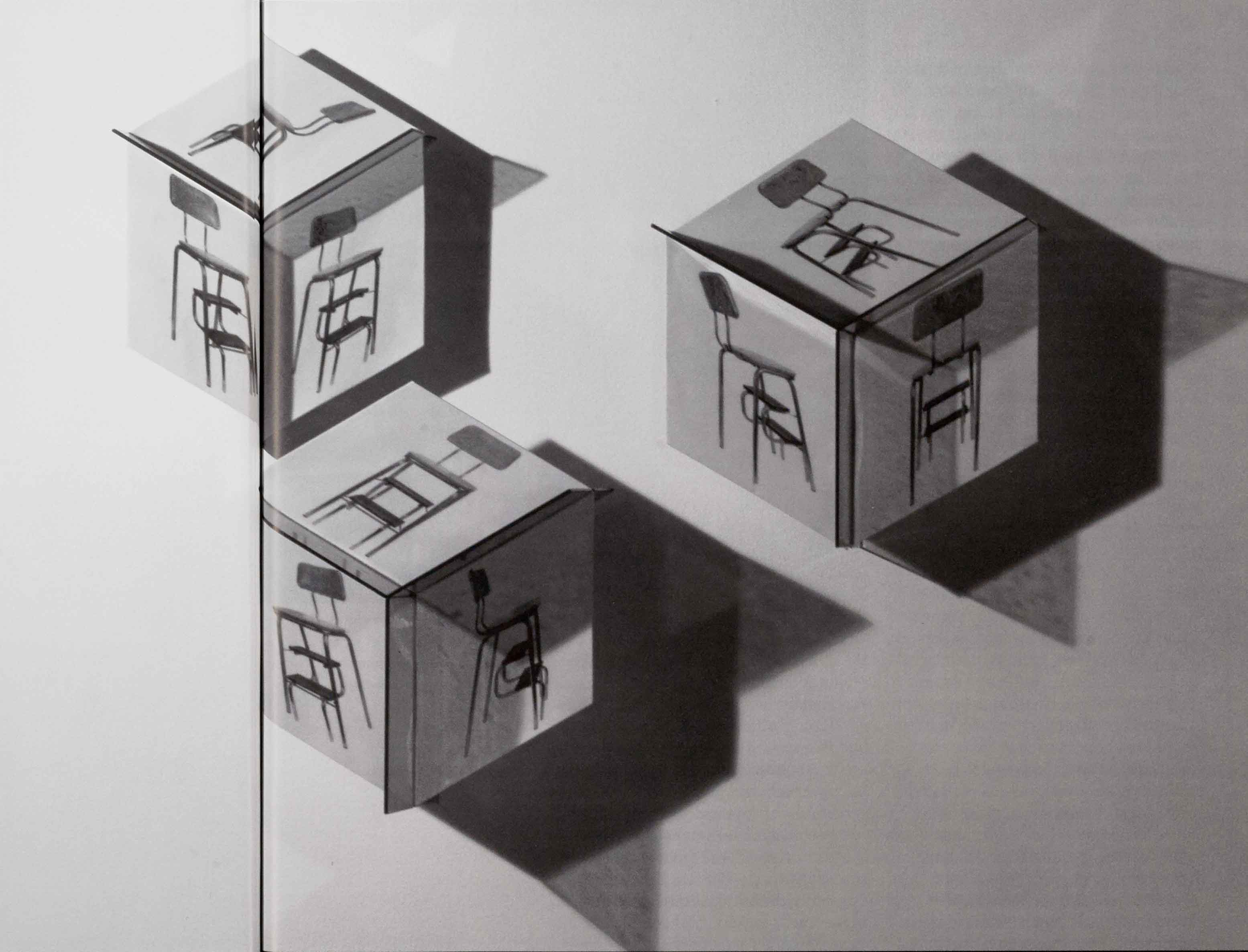

A water-jet cutter is a tool capable of slicing into strong resistant materials, such as metal or fired ceramic, using a high-pressure, high-velocity jet of water or a mixture of water and an abrasive. Another option is a 3-D laser cutter, which works by directing the output of a high-powered laser beam onto the material to be cut. The material then either melts, burns, vaporizes, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. I have been using a 3-D laser cutter on the surface of glazed work, porcelain bisque, sheets of acrylic, mirrors, and recently on flexible rubber to create my own imprinting tools for working back into the wet clay surface.

Cost Factors and Developing Curricula

Many of these pieces of equipment are costly, especially the water-jet cutter at $20,000 to $40,000. In addition, they require regular service, and in school settings student use can be problematic to monitor. Funding needs to be allocated for a technician to maintain and operate the equipment. Like other electronic equipment, the price will drop and the technology will be refined as time moves forward. The tools mentioned above have already been introduced into many industrial, interior, and product design programs. I believe that these tools are relevant and should be available to our ceramic students on a limited basis, and that within ten years many schools will have rapid prototyping and 3-D laser cutters in their art facilities. Now is the time to carefully consider how we can adapt, develop, and distinguish individual studio art programs. If we take time to thoughtfully create exciting new curricula, we will usher in a melding of realms, where handwork mixed with digital tools will produce innovative ceramic art.

Folding these new technologies into our current curriculum can be problematic and complicated. Having taught at both state universities and liberal arts colleges, I have observed that the impetus to change a curriculum is usually pushed forward by the following factors: a new, energetic faculty member; university administrators with an agenda to change the mission of the art department; or an accreditation review on the horizon. Usually the writing of new curricula happens across disciplines. Our current model of studio education separates out according to materials and disciplines. The painting, sculpture, and printmaking areas, as well as ceramics, have distinct sets of course maps. In the past ten years many university programs and art schools, such as the University of Michigan, have merged formerly distinct areas and organized the media into 2-D and 3-D divisions. It is now common to see ceramics and sculpture grouped together, sharing a curriculum and facility, with some benefits to both areas and some loss for the individual media. With the advent of computer-assisted technologies, which serve specific media areas, art studios will require adjacent computer rooms to facilitate the interface between the technical and the application processes. Additionally, there is the possibility of cross-fertilization with other media areas, such as printmaking with digital ceramic printing.

This particular system works well for the studio art program at FSU. We already have a strong interdisciplinary model, which we call an "intramedia" approach, meaning that students use any art medium that serves their ideas. Ceramics has become one of many materials a student may choose to investigate. This encourages those who are painters to work in clay and vice versa. We have very few students who make straight ceramic art; most use other materials alongside their clay work. This has had a few interesting side effects. The hierarchy of materials falls away, and ceramics is considered as viable as any other material. I do make a point of acknowledging the contemporary craft side of ceramics in my classes so that students understand that ceramics has a different material history. When visiting artist Anne Drew Potter came to campus this year, she pointed out the importance of seeing ceramics in many of the nonceramicists' studios, concluding that to them it was simply another valid material. I agree that this serves our program well. It is easier to make a case for adding new technologies if they serve multiple areas of a studio art program.

FSU's studio art approach is but one of many existing models in higher education. Currently there are a handful of universities and art schools in the United States that teach a curriculum using a platform of core ceramic classes coupled with thematic programming. The School of the Art Institute of Chicago is one example; it offers an Extreme Craft course and a Designed Object class that uses rapid prototyping. These thematic classes follow cultural trends and mirror issues in contemporary art. The thematic trends in our studio art programs are cyclical and based on the aesthetic hierarchies that are fashionable. The problem seems to be finding a curriculum that provides a core foundation and in-depth overview of ceramic techniques while also exploring contemporary issues and leaving some wiggle room for students to independently make inventive work. When advanced information or a highly skilled technique is needed, will these students need to outsource the technical aspects of working in ceramics to others?

Economies of scale will force many schools to adopt interdisciplinary programs, pairing disciplines and specialties together. In the United Kingdom, many ceramic programs have been cut, and others with PhD programs work with industry in order to defray costs. The downside of this is a possible conflict of interest with corporate research and a lack of investment in undergraduate education. The Royal College of Art in London, which houses the Applied Art Research-Ceramics & Glass School, has an interesting phrase on its web site: "The materiality of everyday life in a digital age," which succinctly describes the intersections taking place both within and outside academia in England today. Will this leap forward into a digital future create a backlash? I know that I am not alone in the satisfaction I derive from touching wet clay versus pushing keys on my laptop. We need only look to the wood-firing explosion that began in the 1990s and continues today to see the desire for working directly with materials in real time. At the same time, students and young makers are increasingly comfortable using the Internet as a tool for dialogue, sharing information, and marketing. Blogs such as Crafttastrophe, Extremecraft, and Craftmafia, disseminate information and provoke and connect makers around the globe. The blog Crafthaus has an ongoing debate on computer-aided design (CAD) versus handwork, and another on rapid prototyping. I believe this is what the future holds for our students. Those of us who teach need to reflect, engage, distill, and take these ideas into the classroom. I am excited to see what our students will create when they take their digital fluency and reinvent ceramics in ways we can't begin to imagine.