Claire Warnier and Dries Verbruggen founded Unfold in 2002, after they graduated from the Design Academy Eindhoven, in The Netherlands, to develop design projects that investigate new ways of creating, manufacturing, financing, and distributing in changing global contexts. The Antwerp-based duo have a strong multidisciplinary background in design, technology, and art. They exhibit their work internationally and often collaborate with a vast network of kindred spirits and specialists. This interview was conducted in 2018 via email for Studio Potter.

Claire Warnier and Dries Verbruggen founded Unfold in 2002, after they graduated from the Design Academy Eindhoven, in The Netherlands, to develop design projects that investigate new ways of creating, manufacturing, financing, and distributing in changing global contexts. The Antwerp-based duo have a strong multidisciplinary background in design, technology, and art. They exhibit their work internationally and often collaborate with a vast network of kindred spirits and specialists. This interview was conducted in 2018 via email for Studio Potter.

BC: I often refer to Unfold as the parent of clay 3-D printing. How would you describe your work in clay before direct clay printing, and how do you understand your relationship to the material now that you’ve been 3-D printing in clay for more than ten years?

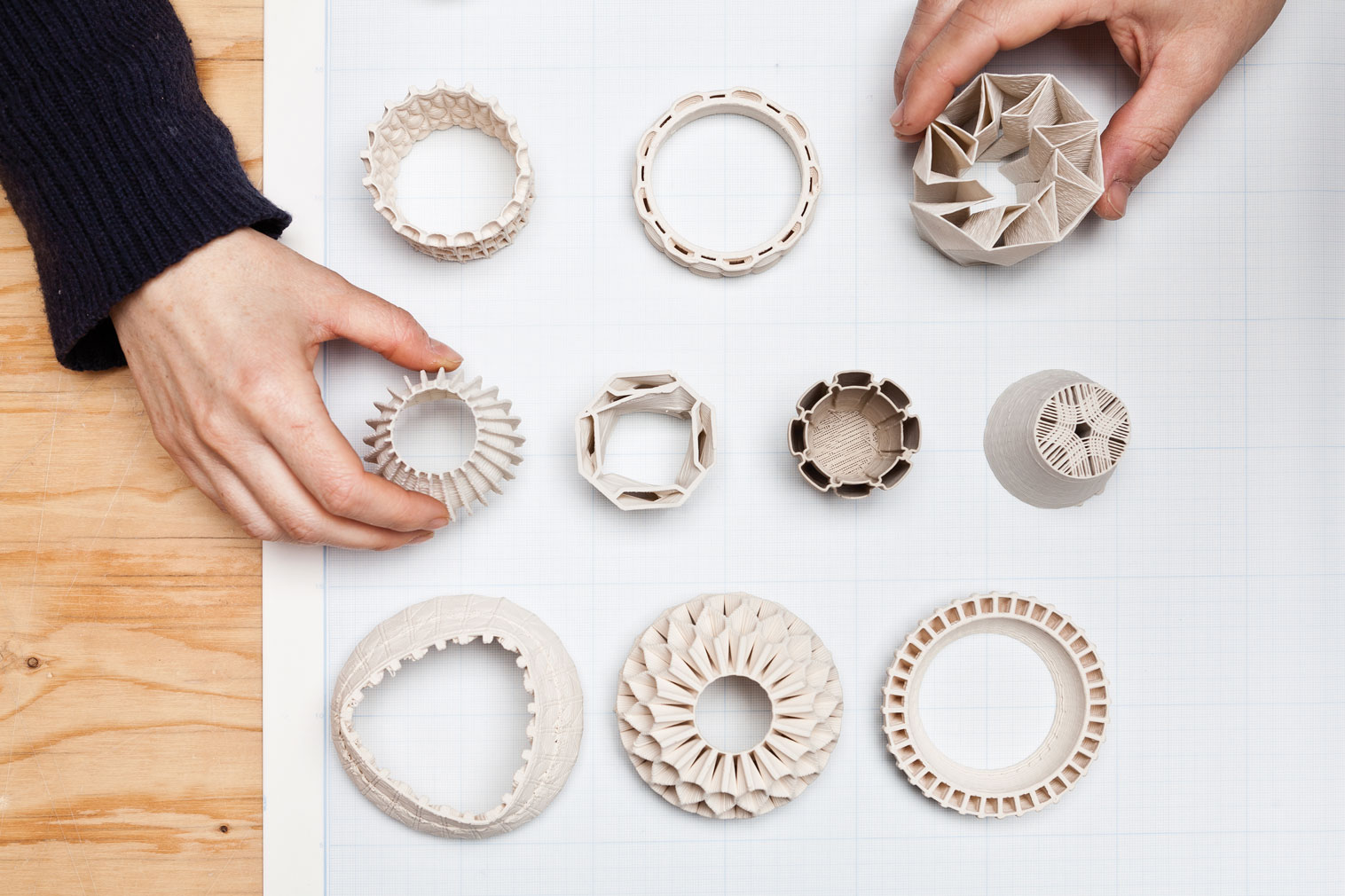

U: 2019 is the tenth birthday of this “child,” so hopefully we can organize a little party! (Actually, we do have two human children as well as two rabbits, two fish, and one bird.) We appreciate that people attribute the initial development of extrusion-based ceramic 3-D printing to us, but we are also standing on the shoulders of giants like the RepRap project. Just as you would a child, in the early days we had to nurture [the technology] a lot and develop many of those extruders and tools. We’re really happy that today it has grown up and it’s fully standing on its own legs in a healthy community.

We’ve always been very fond of the material world. Even though we were fascinated by the malleability and interactive nature of the digital, we rejected the notion of screens as the medium on which digital should be experienced. We love the consequences and collateral side effects of working with physical materials, their weight, smell, texture. Brancusi said, “You cannot make what you want to make but what the material permits you to make. You cannot make out of wood what you should make out of stone, and you cannot make out of stone what you need to make out of wood.” That is often forgotten when a young design student drags a material texture from their library onto a generic CAD model.