Towards an Aesthetic of Digital Clay

By now digital technology has affected studio practices for all of us. In this talk we're not going to talk about marketing, branding, or digital images, which have all had significant ramifications for the ceramic artist's studio practice. Instead, we're focusing on digital information and technology as it is directly affecting the creation of ceramic forms and surfaces - what's known as digital fabrication - and how that is beginning to operate in our studios. Over the last five or so years, Andy and I have spent a lot of time in conversations that start out with some really specific technical question about tools or technology, then evolve into a broader conversation about how studios are changing, and what the theoretical and conceptual implications of the tools and processes might be.

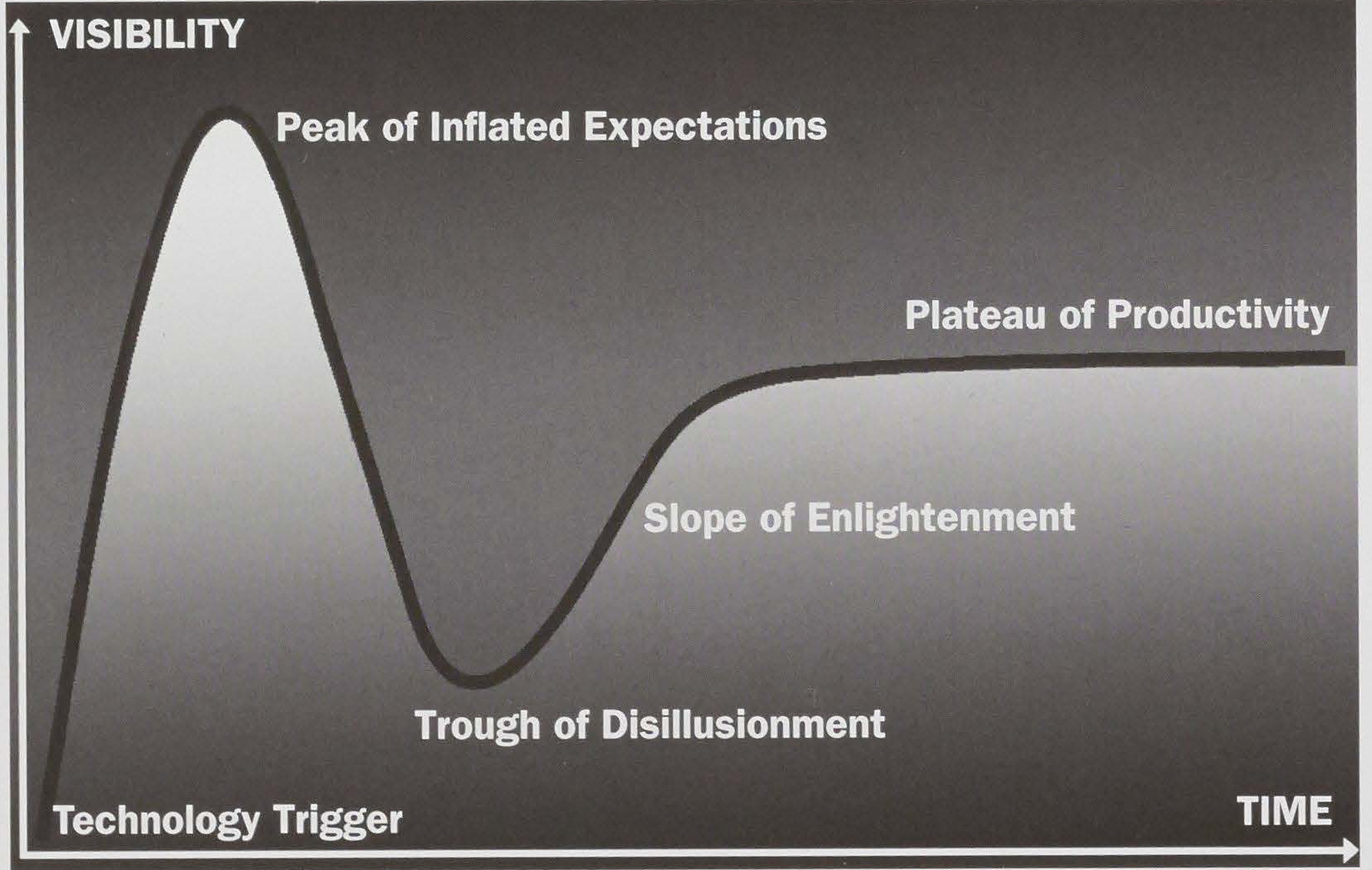

The Gartner Hype Cycle

The Gartner Hype Cycle is a branded graphic developed by the Gartner Research Group to describe the adoption and application of specific technologies. It describes three distinct phases of cultural visibility following the "technological trigger," or introduction of a new technology. The Hype Cycle is often brought up in discussions of technology, and many of us have experienced these phases and understand them intuitively, even if we haven't described the experience to ourselves so clearly. The diagram is interesting within the context of this talk because it illustrates some of the feelings that many of us have about new technology: both our excitement and our trepidation and skepticism. While the part of this graph that we all understand intuitively is the left h a l f - with flying cars, monorails, the paper-clip helper on Microsoft Word, and the Hubble space telescope coming to mind-we spend less time thinking about technology as it moves through the second half of the cycle. That's where Andy and I feel we're working, and what this talk is focused on. While we are aware of the common bugs and shortcomings of technologies as they are introduced into our culture - their failure to live up to the hype - we are also both in the group that is interested in new developments.

Andy and I started to incorporate digital tools into our studios fairly early on, at least in terms of the tools' maturity and widespread use in ceramics. Probably most of the ceramic artists who are currently using digital tools are similar; we are what are called "early adopters." Tools used by early adopters tend to be used in certain ways and produce particular kinds of outcomes. A good example of this is the way personal computers were primarily used before Apple and Windows interfaces made them widely accessible. Because of their cost and the technical expertise necessary to use them at that time, computers were used mainly for highly technical problems. Most users had extensive training in mathematics and computer science, so the kinds of things they did with computers were closely connected to the structure of the computer as a fundamentally mathematical machine. Today, computers are used by almost everyone, and for a tremendous range of applications extending far beyond their early uses.

We're interested in how the use of digital tools in ceramics will change once later adopters start to play with them. Many forms produced with digital fabrication have a "digital look," which comes in part from the tendency of early adopters to be interested in the tools themselves and their tendency to make things that look conspicuously like they were made with computer-controlled machines. As digital fabrication tools come to be used more widely, we'll likely see them applied to ideas and uses further removed from their core structure, and hopefully see a wider range of forms and aesthetic qualities.

Studio Pottery and Variation

While the economic advantages of more mechanized processes in the production of pottery (or material culture in general) are pretty obvious, there is a downside. But we see these disadvantages in aesthetic terms rather than economic ones: for instance, the homogeneity of objects made using highly mechanized processes and tooling. In contrast to the flexibility and evolving formal variety of work created by smallscale and more manual production models such as studio pottery, highly mechanized processes usually produce an original and then a series of exact replicas.

David Pye's essay The Nature and Art of Workmanship offers a pretty clear way of thinking about these ideas. Since virtually everything made by humans depends on some degree of tooling or technology, Pye presents the relationship between (more) mechanized and (more) manual fabrication as a continuum. Manual fabrication is characterized by Pye's term "the workmanship of risk," in which the outcome is uncertain and dependent on the skill and attention of the maker, while more mechanized fabrication (involving more developed jigs, molds, and tooling) is characterized as the "workmanship of certainty," in which the quality of the work is largely controlled and determined by these tools. Pye makes a case for the continued existence of the "workmanship of risk," saying that "when the workmanship of certainty remakes our whole environment, as it is bound now to do, it will also change the visible quality of it." His argument can be summarized as a belief in the innate human need for variety in material culture (like the morphological variety present in the natural world) and a conviction that this variety is possible only through preservation of the workmanship of risk. He illustrates his point with the "variety of qualities" present in works in the British Museum, most of which were produced employing a high degree of workmanship of risk, in comparison with the homogeneity of forms in the average modern department store, where nearly everything is produced through processes characterized by the workmanship of certainty.

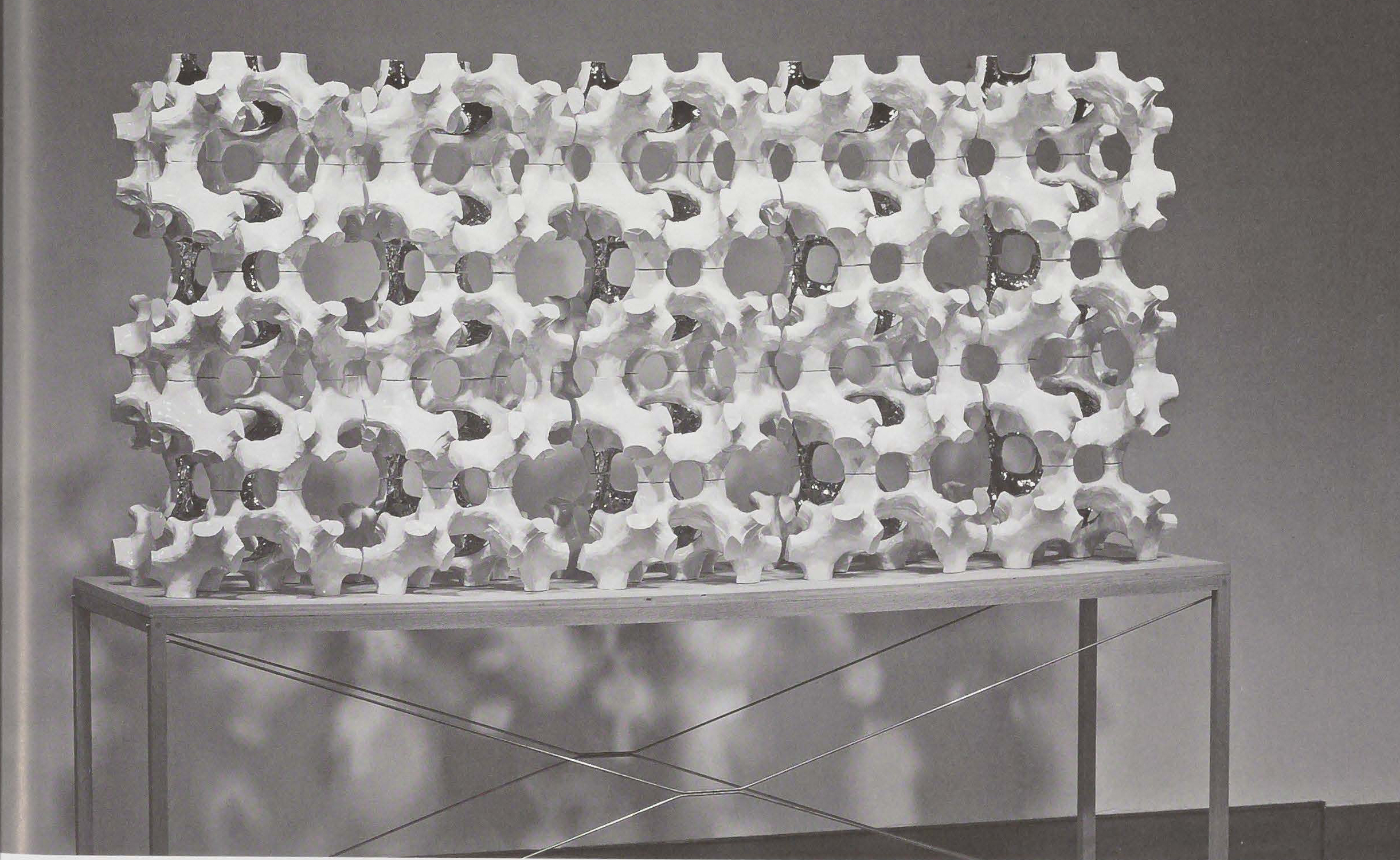

The fields of studio pottery and the crafts have, to an extent, defined themselves by their differences from industrial production. In studio pottery, the judicious use of technology and mechanization allows for creating series of highly variable objects through iterations. But digital fabrication tools are fundamentally different from earlier mechanized ones, in that they offer another level of flexibility. With tools that can move in multiple ways by employing multiple axes of travel, and software that makes that movement increasingly fast and easy to program, one can create complex and variable movement that is also highly adaptable. Digital fabrication has the upside of Pye's workmanship of certainty - namely, precision and speed - but it can also create variation in forms and decoration that in the past could be achieved only through the workmanship of risk. (It's worth mentioning that Pye suggested this possibility: "Diversity in shapes and surfaces could also no doubt be achieved fairly crudely by numerically controlled machine tools, and perhaps something more can be hoped for there in the course of time." In 1969, the year of his essay, this possibility wasn't really tenable, but to a certain extent digital technology has now made the kind of diversity Pye is alluding to technologically feasible, if not yet a reality.)

In manufacturing, this current situation is sometimes referred to as the next Industrial Revolution, or "agile manufacturing." More flexible mechanized tools allow for small-batch production that wasn't economically feasible in the past. It's important to be really clear that agile manufacturing isn't just coming out of a recent invention of one machine or a few new kinds of machines, but is the product of a simultaneous flowering of connected technologies. While the tools themselves have been around since the sixties, the present "next Industrial Revolution" is probably the result of a confluence of different factors: the development of more and more powerful computers in smaller and smaller packages; programming languages that are easy to use and tailored to specific applications; and highly technical information becoming easily accessible through the Internet and the World Wide Web. We've also seen a significant decrease in the cost of hardware, which has given individual studio artists - whose goals may not be the same as those of industry - access to digital fabrication tools.

Digital Fabrication in our Studios

Let's look at some specific types of formal variation made possible by current digital fabrication technology. We're using a few basic tools and software, but we believe that these same formal and aesthetic categories apply to a broad range of tools. One kind of formal variation is a gradient, where one feature, a dimension or a color, changes in a precise way either over a large space or a large series. Morphology refers to iterations that vary forms in a precise way through a large series; each variant is a result of emergent and/or layered complexity All of these are parametric, in that you have to define

all of the variables at the beginning. But computation power is now so cheap and software so sophisticated that playing with those parameters can be dynamic (relatively simple) and the simulations happen in real time, so you can see the effects of manipulating variables very quickly. This has raised an interesting question: is there a difference between the kind of variation achieved through "computer assisted" production and the kind that a studio potter might explore through iterative making, using the workmanship of risk? In either case, there is a human operator. Another, more precise way to frame this question would be: is it important that there be consciousness present at the moment when the process moves from one variant to the next?

You could assume that in this picture we're painting, all these developments in digital fabrication are going to lead inevitably to more variety from industry, more choices for consumers, and more possibility and variation in material culture. But Neal French, a British industrial designer, makes an interesting counter-argument. French argues that prior to the introduction of CADCAM in British tableware industry, there was actually more variety and formal experimentation. What we might call the old model of designing a new product involved a close relationship between a designer and modeler, using freehand drawing and carved and turned plaster models. In French's opinion, aesthetic variety came out of the designer's level of intimacy with the prototyping process. What one could think of as the limitations of tools, such as plaster and the lathe, were actually starting points for aesthetic play. In contrast, with the introduction of CAD modeling the primary relationship in the design process is between the designer, working directly with the computer or computer operator, and consumer testing groups. French believes that the result of this shift has been an overall standardization of forms. As the results of market tests are parsed and averaged, the outcome becomes more and more the same.

Either as a cause or result, the production cycle has also sped up significantly. Whereas the old model could require years for a new form to enter the marketplace, with the introduction of CAD and CAM processes, new forms can go from the designer's computer to the market in a few weeks.

Exploring the Limitations of Tools

Digital tools and machines still have particular limitations and tendencies, which paradoxically may lead to the late adopters of new technologies using them in unexpected ways. Studio potters are already familiar with this, in the example of a technology such as the potter's wheel. If you were to plot the location of the wheel as a technology on the Gartner Hype Cycle, it would be really far out on the "plateau of productivity," yet potters continue to produce unique and highly varied forms out of a deep investigation of this established technology.

So while we would still categorize ourselves as relatively early adopters in the use of digital fabrication technology in the ceramics field, we also each have a background working with ceramics and craft processes. There are things that we've noticed, and are exploring in our work, that might come out of late-adopter thinking: looking at what could be thought of as limitations of these tools but can also be thought about as both practical and aesthetic opportunities.

For example, 3-axis milling machines (and reductive carving in general) tend to produce tooling marks. The presence of these marks is typically seen as trade-off, because finer tooling that will erase them requires more machine time. But the marks can also be seen as an aesthetic effect. Beyond simply leaving a mark of the process, the movement of the tool over an object can be controlled in a way that creates the desired form while yielding an ornamental patterning. 3-Axis milling machines also tend to be both less expensive and easier to program than machines with additional axes of travel. But they have the "limitation," because of their limited movement, of not being able to carve undercuts or forms in the round. Making more complex, dimensional forms with these machines has typically required either complicated jiggering and clamping in order to address additional surfaces or else elaborate assembly after the milling process. However, when 3-axis machines are used to make molds for slip-casting, press-molding, or RAM pressing ceramics, these limitations disappear. When an object is "parted" for casting, no part can have any undercuts, and since the limitations of a mold part are virtually identical to those of the 3-axis machine, any mold part can be made on machines of this kind.

Finally, visible meshes and triangulation are typically considered an artifact of the 3-D modeling process and also understood as a mark or texture that makes the structure of virtual objects visible. However, this texture can be seen as both ornamental and conceptual, a kind of "truth to materials," because the structure of the system isn't covered by another skin. This might be seen as similar to ideas about truth to materials present in wabi-sabi pottery or modernist architecture. On the other hand, this kind of mark can also be a kind of stylization, or visual cliche, a frequent result of the overuse of same tool set, or a fetishizing of the tools and the idea of the technological. It can be seen as "what the contemporary looks like," but in a way that is more about surface effects than about asking deeper questions.

Other Possibilities (The Future of Software and Tooling)

Another idea that we're exploring in the studio is the development of new tools: expanding the possibilities of digital tools by participating in the development of new technology. This might sound like an impossibly complicated proposition involving years of training in computer science or engineering. But it's possible today to become an active participant in the development of software and tools with relatively little formal technical training, because of some fundamental changes in the way both hardware and software are developed. On the software side, there is a change that we think started with the advent of what's known as object-oriented programming. This is the idea that a program, rather than being created out of a sequential list of instructions, is instead understood as a system of interacting objects. This allows for programming and scripting languages that work sort of like a kit of preassembled parts.

We both make extensive use in our studios of software called Grasshopper. Your role as the "programmer" is to make the connections in the form of a visual diagram between bits of computer code that have already been created and are provided for you. You don't have to understand exactly how all the parts work, or know all the complicated work that went into creating them. With a little bit more study, you can even create your own components and then share them with other users. This is an idea that we think is really fundamental to both digital fabrication and the field of ceramics: participating in a collaborative network of people who are both using the tools and also contributing to their development. When you look at the whole system, all the way from software to the final material outcome, it's just too complex for one person working in isolation to deal with and build every part.

Today the line between the programmer and end user is blurring: we think this is a good thing for artists and creativity. Using powerful software sometimes feels as though you're creating by selection, or that the look and feel of the thing you made are as much the work of the software designer as they are of yours. Our current process of using CNC tools requires at least three separate software applications to get from the design stage to the machine stage. As you move from each piece of software to the next, you have to stop, save your work, and export a file. From the point of view of creative process, this feels like a really significant interruption, which creates a distance between the development and the physical realization of a form. It's nowhere near as seamless and fluid as manipulating a piece of clay directly with your hands, and there is a skill to get good at navigating that remove. There may be an analogous "remove" in traditional ceramic processes, such as waiting for results to come out of the kiln, but in the case of digital fabrication, we can also work toward creating tools that close this distance.

Another limitation still present in much of the work we've described comes from the use of any kind of mold. The investment one makes in creating the mold makes iterative variation much less efficient; for every new form a new mold is required. A number of artists are currently developing processes for both building and decorating ceramics forms directly or additively, using CNC machines.

Conclusion

Why should studio ceramists use computers and digital fabrication technology? Clearly, Andy's and my interest in this technology goes beyond the straightforward functional outcomes of precision, speed, and scalability that we often associate with digital technology. We are interested in exploring the particular formal possibilities and aesthetic qualities made possible through new

and varied techniques. From this point of view, the answer to this question may be surprisingly similar to another: Why should artists continue to make things by hand? If we assume, as David Pye predicted, that through the use of digital fabrication technology we'll soon be able to achieve any level of variety and complexity in material culture, what is the use of continuing to make things that explore the workmanship of risk?

It seems evident, especially to those trained and experienced in making by hand, that the way we work and make affects the way we think. Beyond the short-term goals of achieving formal effects and variety in material culture, the process of making deeply shapes the cognitive experience of the maker. If this is true, then what we are striving for in the studio, through the use of new and hybrid technologies, is a deeper kind of variety. Beyond the immediate effect of production processes on material culture, we aim for variety in the ways we think about making and the ways in which making is thinking. We believe that this variety will ultimately contribute to a deeper and long-term variety in the pots we make and the world we build.

Reference:

French, Neal. "CAD CAM and the British Tableware Industry," in The Culture of Craft, Peter Dormer, Editor. Manchester:Manchester University Press, 1997.

Pye, David. The Nature and Art of Workmanship. Cambridge: Cambridge University Press, 1978.