Choosing Another Path

My first experience with clay was in 1950. I modeled forms from which I made a press mold and produced two or three pieces. I also made models for a group of lamp bases that were reproduced by casting. I worked for a short time in a factory as a designer, earning a basic wage in production glaze spraying.

Such was my introduction to the world of ceramics. My Bauhaus training in the art department of Brooklyn College had left me quite open to the idea of the artist/designer of mass-produced goods. I envied those Scandinavian artists who had the opportunity to pursue their individual work as well as see some of their designs carried out in the factory.

Later, as I learned to throw, the pleasure and immediacy of this way of forming clay gave me my direction. I read the writings of Bernard Leach, Shoji Hamada, Michael Cardew, and, subsequently, Philip Rawson and placed myself in their tradition. Clay formed by the hands of conscious, caring potters imparts a spirit to the work that resides in the fired piece. I love the fact that many thousands of my pieces carry into people's homes the gift of immediacy of my hand on clay. Only a piece made by hand has the particular quality of transmission of spirit from maker to receiver.

A piece designed for production, on the other hand, lives in another place. It has been so carefully considered, its shape and contours honed to the perfection that mechanical forming demands, whether by casting or Ram-pressing. The designer's ideas can move from the abstract into exquisite symmetry, and beautiful work may be produced. When a designer has this intention, strong work is made in quantity which is unique to these methods. It is possible for a potter to move into designing and learn the necessary technical processes.

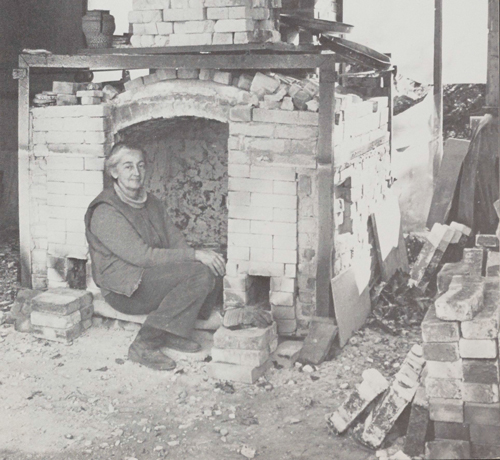

One may still equip a handworking studio with only a relatively modest investment, even though our ceramic materials have increased in cost. To set up one's own small factory, however, calls for major changes. Purchasing a Ram press or casting system, and subsequently the large studio and kiln needed to justify production, is expensive. More important is consideration of the amount of daily work required—mixing large amounts of clay and operating the ram press, making slip and pouring molds, glazing and firing all the ware, then packing for shipment. Also needed are the technical skills of overseeing quality control, plus the ability to organize and manage details of an office. After the employees are paid, will the potter/factory owner's income be substantially higher? Finally, there is the distribution of this volume of finished ware through catalogues, agents, and large professional fairs. The concerns of running a factory are totally different from those of the individual potter. In the 1960s it was common practice for shop buyers to come to the potter's studio where they could choose pieces to buy. They enjoyed the advantage of richness and variety in a small studio where work was changing and growing. They shared in the process and made a commitment to the potter when they bought work. Today many shops have become galleries that schedule so-called shows, with potters often paying for the shipping of work to stock the shelves every month. A resumé of shows does not necessarily reflect income from sales.

As the numbers of potters and shops increased, the wholesale fair gathered them into one place. We saw the tremendous growth of our field, reflecting the growing economy. Many potters, under pressure to be competitive in this large marketplace, narrowed their work so it could be more easily described in a catalogue of particular items. Buyers were permitted to expect exact reproductions of pieces in volume, and potters at the fairs often accepted orders for the next year's production. Thus they have allowed the repetitiveness of mass production to dominate their individual studio work. One can understand the temptation to take the next step into mechanical reproduction.

But there is another path before us, and that is to remember why we chose clay in the first place. We chose clay because it was a real and meaningful life decision. The challenge today, therefore, is for the individual potter to work more thoughtfully and sensitively, so that what is made speaks even more deeply of the heart and hand that made it. In this way our unique objects will have a place in the market.

This article originally appeared in Volume 15, Number 1 Winter/Spring 1986.