A Bourry Box Kiln, by Karen Karnes

For twenty-five years I worked in my studio in Stony Point, New York, with an oil downdraft kiln which had forty five feet of packing space. For the last ten years of that time I fired mainly the forty cubic foot, natural gas salt kiln I had built. When Ann Stannard and I decided to move to a more rural environment, we chose Vermont, one reason being that here we could easily find the fuel for the large wood-burning kiln we wanted to build. Ann had worked with woodfiring kilns in England before she came to share my studio in 1970. She had told me about a pulling kiln as compared to a pushing kiln, and had given me a new understanding about kilns. In this country, many of us received our pottery education in universities where there were high temperature oil and gas kilns. The firing was essentially a way to get the ware done, and not an aesthetic experience. In those types of kilns, the flame is forced inside under pressure-they are boxes with burners that roar. Ann described instead the quiet hum as the flame is pulled into the chamber and up the chimney. I worked with her in kilnbuilding workshops where we built and fired small woodfiring kilns, and I knew that I wanted to work with wood one day.

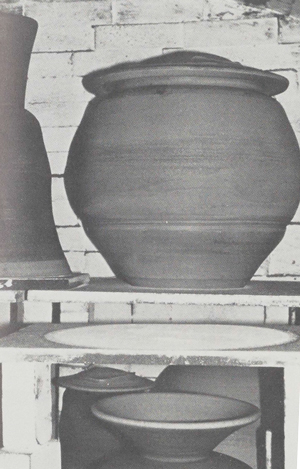

In Vermont we used the plans given to us by potter Ray Finch of England. (See SP, Vol. 8, No. 2, "Woodfiring with a Bourry Box Kiln," by Ann Stannard.) A group of potter friends built the kiln with us. It stands like a temple-the fireboxes massive on each side. I can stand inside and stretch my arms in both directions-so much space to fill! When we were planning its size, and had considered a cart kiln for the ease of packing, we realized that a really large kiln would be a back-saving alternative. Since two of us can put the heavy shelves in place as we stand inside, the packing of the kiln is not difficult.

We have now learned how to fire the kiln. The kiln has four fireboxes, each with its individual ash pit. On the day we pack the kiln, we start a fire in one of the ash pits and keep it going overnight, feeding it with hardwood. At 5:00 A.M., when I start the day, the kiln is about 240°C. We know everything is dry, and the chimney is pulling well. In the next four hours, the temperature is raised slowly by gradually building up fires in all the ash pits, using all kinds of trash wood. By the time the kiln temperature is 600°C, the ash pits are full of burning embers and are very hot.

We stuff the ash pits with wood, brick them closed, and start feeding the Bourry boxes with slab wood. We open each firebox door in turn, and start by throwing in a few pieces of wood. The slabwood has been cut to size, and it lands on a ledge projecting from the wall, so that it hangs above the ash pit. As it ignites, it drops onto the ash pile.

It is a downdraft firebox and there is no blast of heated air as the door is opened during the feeding of the box. We reduce by making slight adjustments in the air intakes, and we change the pull of the chimney by varying the placement of bricks, partially sealing an opening over the damper plate. The sensitive kiln responds to the smallest change, and we judge the internal atmosphere by inspecting the flame in the top spyhole and by listening to the quality of the humming flames, the crackling of lively burning in the firebox.

For me, the day of firing is a day of excitement and joy. Prior to that is make-ready day-there are many shelves to clean in such a big kiln, the small amount of ash left in the pits must be cleaned out, and the kiln walls must be painted where necessary. It is all part of the work cycle, and we fire about every six weeks.

The firing time is from 5:00 A.M. to 6:00 P.M. or 8:00 P.M., when we reach temperature-cone 10 in the bottom, cone 11 on top. We soak the kiln at 875°C and 1100°C. The kiln is very responsive to dry wood, and we judge how much wood to put into the firebox by the rate at which we want the temperature to climb. I have a good friend, Vanna, who fires with me. She is not a potter, but a person who loves firing and shares my work and my pleasure in the whole process. Ann gets up in the night to tend the hardwood fire, then Vanna and I do the rest. Three people are ideal, for this allows a break in the routine, but the work could easily be done by two.

The fireboxes and the whole base of the kiln are made of firebrick so that in the early stages of firing-when one wants a slow temperature rise-the firebrick absorbs the heat and holds it to steady the temperature during the firing. The ash pits contain the intense heat of burning embers, and the gases of combustion are efficiently burned through three air controls in each firebox. A variation of one inch of secondary air will change the placement of the flame in the chimney. We fire with the flame just passing the damper plate, never coming out at the top of the stack. As Michael Cardew advises, the burning is all inside the kiln. A small woodfiring kiln often will not reach temperature because the long wood flame rushes out of the chimney, instead of being contained in the kiln.

We moved to Vermont in early October 1979. Immediately we needed to cut, carry, and stack hardwood for heat; we were anxious to gather many cords of slabwood for firing, feeling the winter pressing at us. We have realized now that this work is too hard, physically, for us to do, and thus we buy our heating wood and hire help to cut and move the slabwood. It is a monetary investment in fuel, similar to the purchase of fossil fuels. Only a person who lives in the North can appreciate the satisfaction of a full woodshed.

The first year we struggled to fire with wood that was not totally dry, and we had a greater deposit of ash because of the longer firings. This kind of kiln burns so efficiently that there is only a light trace of ash left on the work. If you want to rely totally on the kiln for ash glaze, you need another kind of kiln.

Now that we are using wood that has been standing well over a year, we see how important that is. The kiln fires so much more easily-we do no splitting of the wood, and find that we can burn a two-inch section. Some local mills are installing chipping machines with which to process their slabs immediately, sowe fear that slabwood—which used to be easily available as a waste productmay soon be unobtainable. Since we have been working with dry wood, we know we could use split logs of softwood, given sufficient drying time. We need about twenty cords of wood per year, since each firing consumes about 2% cords. We plan to move to a new property next summer. We should purchase immediately forty cords of pulpwood, to be delivered to the site and cut and split. In this way, we would have a two year supply of wood drying and could replace half of it annually.

At first I tried to biscuit in the big kiln, but sudden flashes of flame caused cracking in the larger pieces. I have since bought an electric kiln for biscuiting. It is my first experience with electricity. I don't mind at all this casual firing with often only one piece in the kiln at a time. I now understand why potters made saggars to protect their ware.

There is a great interest in woodfiring— witness the survey showing how many woodfired kilns there are in our country alone! Our woodfiring kilns are extending our deep connection with our work, from the making to the end of the process. How hard we potters work, but with so much real satisfaction each day! The hard work of firing is the last phase, with the excitement of controlling fire in an intimate exchange—fire that gives mysterious blessings to the pieces.

Ann Stannard has questioned whether there is a shift among American potters to allowing the kiln to do more work for them. She feels that in the sixties, particularly in this country, people were controlled unconsciously by behavioral scientists. Since that time, she says, there has been a shift to a more spiritual awareness where you can accept that other forces are influencing you and your work.

She sees the emergence of a New Age which will affect people's work and their thinking.

In Vermont there is a deep consciousness of the need for the preservation of resources in these times. The use of wood is not a sentimental return to an earlier age, but a sensitive use of renewable energy. The firing of my work now is a beautiful and meaningful conclusion to each cycle of making pots.

This article orignially appeared in Volume 11, Number 1, Winter/Spring 1982.